Trailed Cherry Harvester

JAGODA 300

Ideal for Small Tree Sour Cherry, & Plum Harvesting

General Informations

Introducing the JAGODA 300: Your Efficient Trailed Cherry Harvester

The JAGODA 300 is an innovative over-the-row trailed cherry harvester designed primarily to efficiently collect berries from plantations prepared for mechanical harvesting. This advanced machine proves remarkably effective on small and young trees that meet specific requirements. However, its capabilities extend beyond traditional harvesting, ensuring a gentle harvest for even the most delicate varieties of sour cherries and plums.

Parameters: Achieve exceptional results with the trailed cherry harvester JAGODA 300

- Optimizing harvesting time at speeds ranging from 0.5 km/h to 1.5 km/h

- Output harvest: From 0.2 ha/h to 0.4 ha/h

- Number of rotor picking heads: 2 Type “BOS”

- Tractor capacity: Min 70 HP

- Harvest Accuracy: Up to 95%

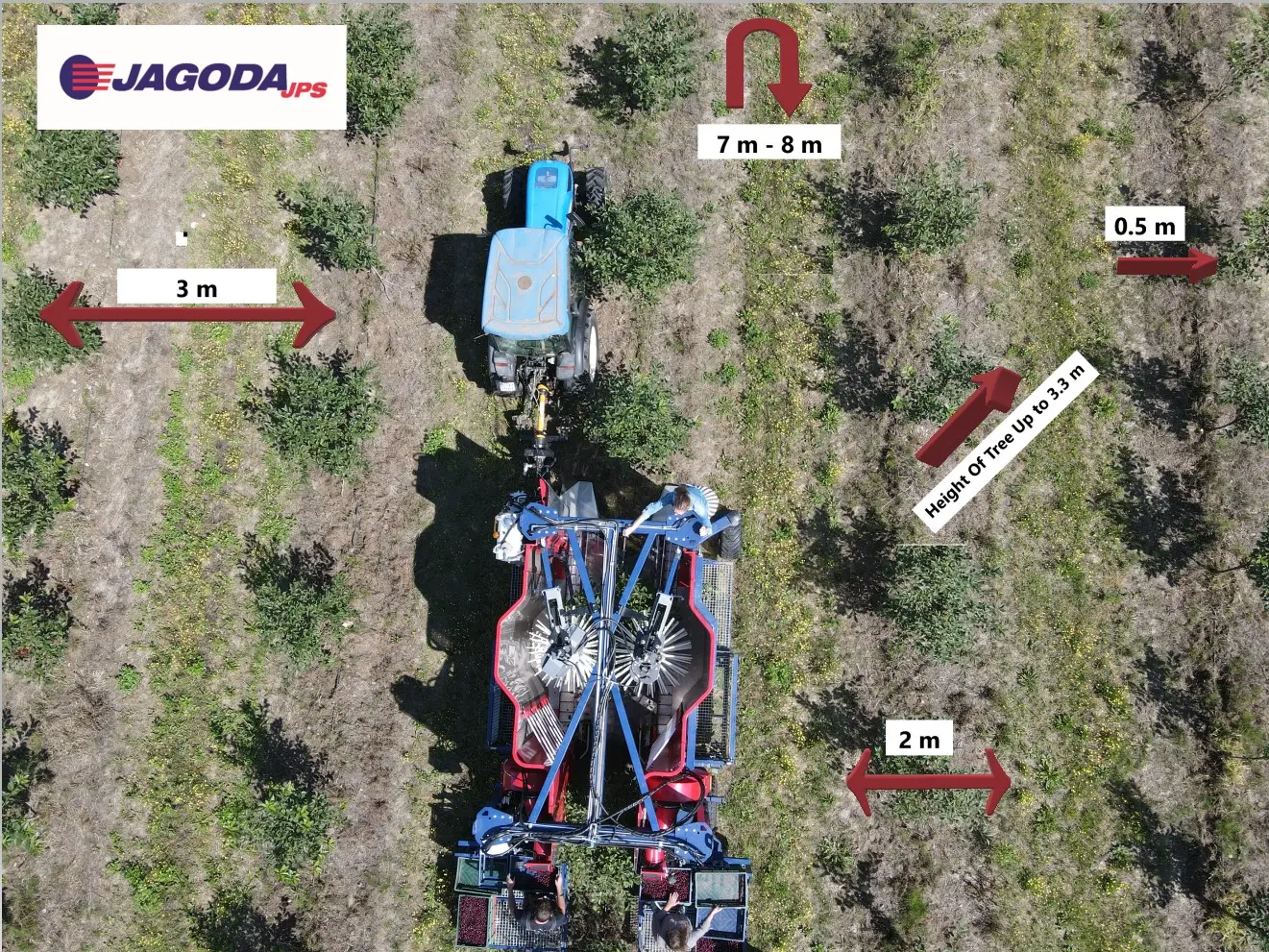

Plantation Parameters:

- Distance between rows: 3 meters

- Trunk height: Min. 0.5 meters

- Tree height: Max 3.3 meters

- Maximum crown diameter: 2 meters with flexible branches (easily bendable)

- Branches should be well-pruned to allow the tree to enter and exit the harvester without damage.

- A narrower crown width is preferable for optimal harvesting efficiency.

- The distance required at the end of the rows: min 6 m – 8 m.

The cherry harvester designed to elevate your operations with its highest workmanship standards and innovative features:

- Hydraulically Adjustable Picking Tunnel: Adapts to various tree heights (up to 3.3m) for a flexible harvesting range (2930mm – 3560mm).

- Efficient Maneuverability: Effortlessly navigate tight spaces with the steering wheels for a smaller turning radius.

- Adjustable Catcher Plates: Strategically placed around the trunk with adjustable height and incline, preventing fruit loss.

- Innovative Shaking System: The two BOS vertical shakers ensure gentle yet effective harvesting for cherries and plums, minimizing post-harvest damage.

- Various shaking element options: sizes (0.5 m/1 m), type (Single /Double) and different hardness options to customize the process harvesting for different fruit types and sensitivities.

- Positioning Hydraulic Platform: Enables convenient fruit collection in both working and transport positions.

- The standard deck holds 20-30 boxes per side (approx. 40-60 total), or accommodates pallet boxes up to 500kg each side.

- Wireless Control System: Take command of all functionalities and settings of the harvester.

- Integrated Drive and Working Lights: Maintain optimal visibility for efficient operation in low-light conditions.

-

Dual High-Speed Fans: Two powerful fans operating at 1000 rpm efficiently remove leaves and debris during harvesting.

-

Single-Drop Fruit Conveyor: Ensures uncompromised fruit quality by minimizing drops and handling.

The JAGODA 300 is the epitome of advanced cherry harvesting technology, offering unmatched efficiency, fruit protection, and user experience.

Contact us today to discover how it can transform your operations!

Technical Specifications

| Mounting: | Two-point hitch linkage, Category 2 |

| Drive (Working Units): | Hydraulic pump via tractor transmission |

| Drive (Internal) | Harvester’s dedicated hydraulics system |

| Staff: | tractor operator + 2 |

| Net Weight | 3 700 Kg |

Contact

+48 46 831 01 96 / Whatsapp: +48 501 782 345

Email: jagoda@jagoda.com.pl

Location

JAGODA JPS

Pamiętna 15c,

96-100 Skierniewice

Poland

Hours

Monday to Friday

From 7 am to 4 pm